Category: Uncategorized

2K Aerosol Plaspaint: New Era in Glass Frosting

The future of glass frosting starts now. Let us explore how to revolutionize glass frosting using the innovative 2K Aerosol Plaspaint Spray. This groundbreaking product offers several advantages over traditional glass frosting techniques. With its easy-to-use aerosol format, you can achieve professional quality results in a small amount of time. The 2K Aerosol Plaspaint Spray is versatile and can be used for various applications, including glassware, windows, and decorative glass surfaces. Its unique formulation allows for precise control and even coverage, ensuring a smooth and consistent finish every time. Compared to other glass frosting techniques, the 2K Aerosol Plaspaint Spray stands out for its superior durability and resistance to chipping and peeling. As the market trends towards more efficient and cost-effective solutions, this innovative spray is quickly gaining popularity among professionals and DIY enthusiasts.

History of Glass Frosting Techniques

Traditional methods such as sandblasting and acid etching were employed to create the frosted effect on glass surfaces. These methods had cultural significance, as they were often used in religious and decorative applications. However, they also had environmental drawbacks, such as using harmful chemicals and generating hazardous waste. In recent years, innovations in contemporary glass frosting have emerged, such as introducing 2K Aerosol Plaspaint Spray. This technology allows for precise and efficient application while minimizing environmental impact. The prospects of glass frosting technology look promising, with the potential for further advancements in efficiency and sustainability.

Challenges faced with traditional methods

Traditional glass frosting methods have presented numerous challenges throughout history. These traditional methods have limits in efficiency, precision, and consistency. A significant challenge was the labor-intensive nature of the process, requiring skilled artisans to manually apply the frosting material onto the glass surface. It resulted in longer production times and increased costs. Aerosol technology allows for efficient and precise application, reducing labor costs and production time. The improved techniques of 2K Aerosol Plaspaint Spray ensure consistent and uniform frosting, resulting in high-quality and visually appealing glass products.

2K Aerosol PlasPaint Spray

Now, let’s look at the 2K Aerosol PlasPaint Spray. This innovative product boasts a range of features that set it apart from traditional glass frosting methods. From its ease of use to its exceptional durability, the 2K Aerosol PlasPaint Spray offers a new era in glass frosting techniques.

What is 2K Aerosol PlasPaint Spray?

2K Aerosol PlasPaint Spray is an innovative spray formulated for glass frosting applications. Its advanced 2K technology ensures a durable, long-lasting finish resistant to scratches and fading. Unlike other sprays, the 2K Aerosol PlasPaint Spray provides exceptional coverage and adhesion, resulting in a smooth and even coating. To maintain the frosted glass’s pristine appearance, it’s recommended to clean it with a mild detergent and a soft cloth. Don’t use abrasive materials or harsh chemicals that may damage the finish.

Features

Experience the remarkable features and distinct advantages of the 2K Aerosol PlasPaint Spray, a revolutionary glass frosting solution. Here’s why this product stands out from traditional methods:

1. Easy Application Process: With the 2K Aerosol PlasPaint Spray, you can effortlessly achieve a professional glass frosting finish. Shake the can and spray it directly onto the glass surface.

2. Superior Benefits: Unlike traditional frosting methods that require lengthy drying times and additional equipment, this aerosol spray dries quickly and evenly. It offers excellent adhesion, durability, UV rays, and weathering resistance.

3. Comparison to Traditional Methods: Compared to traditional frosting techniques, the 2K Aerosol PlasPaint Spray provides a faster, more convenient, and cost-effective solution. It eliminates the need for messy etching creams or expensive sandblasting equipment.

4. Customer Reviews: Customers rave about the 2K Aerosol PlasPaint Spray’s ease of use, consistent results, and long-lasting finish. They appreciate its versatility in transforming glass surfaces, from windows to shower doors, with a professional frosted look.

Advantages of PlasPaint for Glass Frosting

Regarding glass frosting, PlasPaint offers game-changing advantages that can revolutionize your projects. With its precision application, you can achieve intricate designs and consistent results every time. Not only does PlasPaint provide a stunning finish that elevates the appearance of frosted glass, but it also boasts durability, withstanding external factors for long-lasting effects. Plus, the ease of use, thanks to pre-filled aerosol cans and the ‘Colour Match’ software, makes the application process simple and hassle-free.

Precision

Achieve precise and consistent application of intricate designs with the 2K Aerosol PlasPaint spray, revolutionizing glass frosting. This innovative spraying technique allows you to unleash your creativity quickly.

Here’s why the PlasPaint spray is the go-to choice for achieving precise and consistent results:

1. Unparalleled precision: The aerosol spray nozzle delivers a fine mist, ensuring even coverage and precise control over the application, allowing you to create intricate designs accurately.

2. Consistent results: The 2K formula of PlasPaint ensures consistent viscosity and colour and eliminates the need for manual mixing, thus reducing the risk of uneven application.

3. Ease of use: With its user-friendly design, the PlasPaint spray enables even beginners to achieve professional-looking results effortlessly.

4. Versatile application: The PlasPaint spray can be used on various glass surfaces, including windows, doors, and mirrors, expanding your creative possibilities and allowing you to transform any space with ease.

With the 2K Aerosol PlasPaint spray, precision and consistent application are no longer challenges but the foundation of your glass frosting masterpieces.

Durability

PlasPaint is designed for exceptional durability, ensuring longevity and resistance against various environmental elements. It has been rigorously tested to withstand wear and tear, making it ideal for indoor and outdoor applications. This spray exhibits excellent environmental resistance, allowing it to withstand direct exposure to sunlight, moisture, and temperature changes without compromising its integrity. Whether used on windows, doors, or other glass surfaces, PlasPaint maintains its durability and visual appeal over time. With its ability to withstand external factors, PlasPaint offers a reliable and long-lasting solution for glass frosting applications.

Aesthetics

With 2K Aerosol PlasPaint spray, you can effortlessly enhance frosted glass’s appearance, elevating its appeal to new heights. The finished look achieved with this spray is genuinely remarkable, providing a sleek and modern appearance that instantly catches the eye. Here are four reasons why 2K Aerosol PlasPaint is the ultimate choice for glass frosting and beauty enhancement:

1. Crisp and Clear: The spray creates a smooth and even finish, resulting in a flawless frosted effect that enhances the clarity of the glass.

2. Customizable Options: The wide range of colours and finishes allows you to tailor the appearance of the frosted glass to suit your specific design vision.

3. Long-lasting Beauty: The durability of 2K Aerosol PlasPaint ensures that the elevated appearance of the frosted glass will withstand the test of time, maintaining its beauty for years to come.

4. Easy Application: The aerosol format of the spray makes it incredibly easy to apply, allowing for a hassle-free and efficient process.

Ease of Use

Applying 2K Aerosol PlasPaint to frosted glass is a breeze, thanks to the convenience of pre-filled aerosol cans and the user-friendly ‘Colour Match’ software. The simplicity of the application process ensures that even those with little experience can achieve professional results. You can spray immediately with the pre-filled aerosol cans without additional equipment or mixing. The ‘Colour Match’ software takes the guesswork out of finding the perfect colour by allowing you to match any shade easily. This time-saving feature eliminates trial and error, ensuring you achieve the desired colour on your first attempt. The combination of simplicity, convenience, and colour-matching software makes applying 2K Aerosol PlasPaint quick and efficient to achieve stunning results on frosted glass.

Real-life Success Stories

Discover the real-life success stories of satisfied customers who’ve experienced the game-changing advantages of using the 2K Aerosol PlasPaint Spray for glass frosting. From small-scale projects to prominent installations, these testimonials and brief case studies showcase the remarkable results achieved with this innovative solution. You can hear from numerous satisfied customers who’ve successfully used the PlasPaint Spray for glass frosting. Here are some real-life success stories that showcase the benefits, application techniques, longevity, and versatility of this innovative product:

- Improved Aesthetics: Customers have praised the PlasPaint Spray for its ability to transform plain glass into elegant frosted surfaces, adding a touch of sophistication to any space.

- Easy Application: The PlasPaint Spray provides convenience and ease of use with its aerosol formulation. Customers have reported that the application process is quick, smooth, and hassle-free.

- Long-Lasting Results: The PlasPaint Spray offers exceptional durability, ensuring that the frosted effect remains intact for an extended period. Customers have mentioned that the finish withstands daily wear and tear without fading or peeling.

- Diversified Applications: From windows and doors to partitions and decorative glass, the PlasPaint Spray is versatile in various settings, making it a popular choice among residential and commercial customers..

How to Get 2K Aerosol PlasPaint Spray?

1. Superior Availability: Creative Resins ensures a constant 2K Aerosol PlasPaint Spray supply, eliminating delays or stock shortages.

2. Trusted Supplier: With years of experience in the industry, Creative Resins is a reputable company known to deliver high-quality products and excellent customer service.

3. Easy Online Ordering: The user-friendly website allows you to browse and purchase the product effortlessly, saving time and effort.

4. Secure Shipping: Creative Resins guarantees safe and prompt delivery of your order, ensuring that the 2K Aerosol PlasPaint Spray arrives in perfect condition.

Expert in Glass Frosting

Durable, Resistant Corrosion Metal Paint

The revolutionary temperature and water-resistant corrosion metal effect glass paint can withstand extreme temperatures, resist water damage, and remain impervious to fading or scratching. This innovative product has been specially formulated to provide long-lasting protection and beauty to your glass surfaces. Whether it’s windows, doors, or decorative pieces, this remarkable glass paint is designed to endure the harshest conditions without compromising aesthetics. Say goodbye to peeling, chipping, or dullness – with this incredible solution, your glass surfaces will retain their vibrant colors and flawless finish for years. Enter the revolutionary Corrosion Metal Effect Paint – an innovation in surface protection that promises to keep your surfaces looking brand new for years.

What is Corrosion Metal Effect Glass paint?

Corrosion metal effect glass paint is a paint that gives any old or new surface a rustic and aged appearance, adding character and intrigue to an ordinary item. This rust-effect paint is remarkable for its ability to mimic the natural weathering process of metal corrosion. The paint contains unique pigments that react with air and moisture, causing them to oxidize over time. This gradual oxidation gives rise to the distinct orange-brown hues typically associated with rusted metal surfaces. It is realistic and impressive to see and feel the transformative power of a corrosion metal effect glass paint that not only replicates the look of rust but also withstands the test of time. With this innovative paint, you can achieve an authentic and mesmerizing rusty appearance on surfaces without worrying about it fading or scratching away. The innovative formula used in the corrosion metal effect glass paint is unique. It all starts with a base coat that contains real metal and iron particles. When these particles come into contact with an oxidation solution, they begin to rust, creating a stunning and unique metal effect on the glass surface. Some oxidation solutions produce an even uniform corrosion effect on the painted surface. It can help create a weathered look or simulate aged metal objects.

On the other hand, more aggressive solutions can generate an uneven and unpredictable corrosion pattern. It adds a touch of randomness and complexity to the finished piece, making it visually intriguing. How the material is positioned during application can impact the final result, emphasizing certain textures or creating unique patterns. For instance, painting the glass surface horizontally may create a smoother finish, while applying it vertically could give rise to streaks that mimic rusted metal.

Features and Benefits of Corrosion Metal Effect Glass Paint

Water Resistant

One of the key advantages of our corrosion coating cycle is its water resistance. Water can significantly threaten structures as it promotes oxidation and rust formation. However, with our innovative technology, we have found a way to create a protective barrier that repels water l. It not only extends the lifespan of the material but also reduces maintenance costs significantly. Not only does our metal corrosion effect glass paint provide an exceptional aesthetic appeal, but it also boasts impressive performance features. Offering resistance to water exposure, this paint is built to withstand harsh climates without fading or deteriorating. It ensures longevity and durability for outdoor signage, architectural elements, or interior design accents. Metal corrosion Effect paint prevents water molecules from coming into contact with the surface by forming a tight seal that waterproofs the material. It helps to minimize oxidation and decrease the chances of rust formation.

Scratch Resistant

Scratch resistance is a crucial feature in metal corrosion effect paint. Paints that boast scratch resistance ensure that your beautifully painted surfaces stay looking brand new for longer, even in high-traffic areas. It means that not only will your corrosion effect paint have a stunning rustic appearance, but it will also be strong enough to resist scratches from keys, jewelry, or any other object that may come into contact with it. The benefits of scratch resistance extend far beyond just aesthetics – they also help to protect your investment.

Temperature Resistant

When restoring and protecting high-heat surfaces, finding a product that can withstand extreme temperatures is crucial. You can use Corrosion Metal Effect paint – a game-changer in the world of coatings. Unlike traditional paints that may fade or peel when exposed to heat, this innovative formula has been specially formulated to retain its vibrant color and durability even under extreme conditions. One of the critical features of Corrosion Metal Effect paint is its temperature resistance. Able to handle high-heat environments like no other, this product ensures that your surfaces stay protected and attractive for extended periods.

Fade Resistant

The fade resistance property is achieved in metal corrosion effect glass paint through the ingredients used in the formula. These fade-resistant properties ensure that your painted glass surfaces retain their vibrancy and shine for years. High-quality pigments are blended with durable resins that provide excellent adhesion and resistance against UV rays, harsh weather conditions, and even repeated contact with water. This combination creates a protective barrier shielding the pigments from fading or deteriorating. With vibrant colors that don’t lose their intensity or become washed out over time, you can confidently display your painted glass surfaces without worrying about them appearing dull or unsightly too soon.

Application and Longevity of the Paint

One of the most impressive aspects of metal corrosion effect glass paint is its versatility. It can be utilized for domestic and commercial purposes, making it a valuable asset in various settings. This innovative paint adds elegance and uniqueness to the décor in bars, hotels, and restaurants. Its realistic and impressive appearance creates a mesmerizing ambiance that captivates guests. The beauty of the metal oxide effect kit lies in its ability to create an aged and corroded metal effect. This innovative product can be applied over any painted surface, instantly transforming it into a stunning piece of aged artwork. Unlike traditional paints or coatings that quickly fade or scratch over time, this glass paint is temperature and water-resistant, ensuring that your corrosion effect remains intact for years. There is no need to worry about your masterpiece losing its luster under harsh weather conditions – it will continue to evoke the essence of aged metal, even after rains, storms, and scorching sun. Once the corrosion phase is complete, it’s essential to consider preserving the appearance of metal surfaces while ensuring a high resistance level. It is where topcoats come into play. These topcoats protect against external factors such as temperature and water and provide an aesthetically pleasing matte finish that adds sophistication to any surface. A painted surface with a rustic effect can bring an edgy yet elegant aesthetic to any space, whether it’s indoors or outdoors. It means you can enjoy rusty metal’s weathered charm without worrying about fading or scratching.

Where to get the Corrosion metal effect paint at the best prices?

Creative Resins offers premium quality corrosion metal effect glass paint at affordable prices. Its unique formulation provides temperature and water resistance, making it ideal for indoor and outdoor use. Say goodbye to faded and scratched paint jobs, as Creative Resins’ corrosion metal effect paint is designed to withstand even the harshest conditions with a 10-year internal and external warranty. Transform your surfaces today and experience the difference! Call us now at 01795 411820.

Red Oxide Primer: Ultimate Rust Protection

Rust is one of the most common problems that affect metal surfaces. It damages the appearance of metals and weakens them, making them prone to breakage and failure. To prevent rusting, many people use paints specifically designed for this purpose. Red oxide primer spray paint is one such product that has gained immense popularity among professionals and DIY enthusiasts alike. Let us explore why red oxide primer spray paint is the ultimate solution for rust protection and enhanced adhesion. We will discuss its unique properties, benefits, and applications to help you understand why it should be your go-to choice for protecting metal surfaces from corrosion.

What Is Red Oxide Metal Primer?

Red oxide primer is a popular anti-corrosion undercoat designed to prevent rust formation on steel and galvanised materials. This type of primer contains iron oxide. It helps protect the metal from moisture, oxygen, and other elements that can cause corrosion. Red oxide primer is a versatile and reliable coating that can be used in a variety of applications, both indoors and outdoors. It is particularly effective when applied over a surface after it has been sanded down and cleaned thoroughly. The application of red oxide primer usually happens with a brush. Brush coats are notorious for causing dripping, resulting in acute wastage of the paint. When using a brush to apply paint, it is easy for excess paint to accumulate on the bristles, leading to drips that can damage surfaces and requires additional touch-ups. However, you can eliminate this issue using Creative Resins’ Red Oxide Primer Spray Paint instead of traditional brush coats. Red oxide primer spray paint is essential for anyone who wants superior rust protection and increased adhesion on ferrous metals. This specially formulated coating acts as a base coat that provides excellent coverage and corrosion resistance properties, making it the ideal solution for protecting steel surfaces against the harmful effects of rust. Red oxide primer spray paint creates a barrier between the metal surface and the air to prevent oxidation.

Uses of Red Oxide Primer

Red oxide primer is a popular primer with anti-rust and anti-corrosion properties used for interior and exterior ferrous metal surfaces. It is used to prevent the formation of rust on metal surfaces, which can lead to corrosion over time. This primer is beneficial in areas where high humidity or saltwater exposure can cause metal surfaces to corrode quickly.

Benefits of Red Oxide Metal Primer

- Red oxide metal primers are crucial in any painting project involving metals because they are a binding medium for paints and provide excellent adhesion and protection against corrosion.

- When applied over porous materials such as wood, concrete, or masonry, it effectively seals the surface and fills in gaps or imperfections.

- Ferrous metals treated with red oxide primer are much less likely to rust or corrode over time.

- It enhances the life span of your material. By protecting it against rust, corrosion, and other forms of damage, you can significantly extend the lifetime of your metal surfaces. Furthermore, increasing paint adhesion to the surface ensures your paint will last longer without chipping or peeling.

How does Red Oxide Primer Spray Paint help combat rust?

The red oxide primer contains a pigment that acts as an anti-corrosion agent, slowing the oxidation process of iron and steel. This protective layer creates a barrier between the metal surface and external elements such as moisture, oxygen, and salt, which are common catalysts for rust formation. The smooth finish provided by this product will help cover up any blemishes on your metals’ surfaces while providing superior protection against corrosion caused by exposure to saltwater or chemicals.

How to use Red Oxide Primer Spray Paint?

When it comes to using red oxide primer spray paint, there are a few things that you need to keep in mind.

- Firstly, ensure the surface you want to apply to is clean and dry. Any dirt or grease can affect the quality of the primer application.

- Shake the can well and hold it around 8-10 inches from the surface.

- Spray in a sweeping motion, making sure you cover all areas evenly.

- It’s always best to apply two thin coats rather than one thick one, which will help achieve better coverage without drips or runs.

- When it comes to using Red Oxide Primer Spray Paint, combining it with a reducer before application is essential. A reducer is a solvent that helps thin the paint and make it more easily spreadable. The amount of reducer needed will depend on the method of application being used, as well as personal preference. Generally, reducers should make up between 0 and 10% of the final mixture, with most formulas falling in the middle. Adding enough reducer to your Red Oxide Primer Spray Paint can ensure an even coat that dries quickly and adheres well to surfaces.

- After applying the metal primer onto the surface, give it enough time to dry completely.

- Allow six to eight hours for handling after drying.

- Allow eight to ten hours for dry hard.

- Allow it to dry the whole night to recoat

7. After using the Red Oxide Primer Spray Paint, it is essential to understand how to store it properly. The manufacturer’s instructions should be followed carefully to ensure the primer remains in good condition and can be used effectively. Most spray paint primers are flammable and must be stored away from heat sources, sparks, or flames.

8. The primer should also be kept in a cool and dry place with less exposure to sunlight.

In conclusion, Red Oxide Primer Spray Paint is the ultimate solution for rust protection and enhanced adhesion. The unique formulation of this primer creates a strong bond with the surface, ensuring a long-lasting finish. Its corrosion-resistant properties are ideal for metal surfaces exposed to harsh weather conditions or corrosive substances. Moreover, the easy-to-use spray can make application hassle-free and efficient. If you want to ensure your surfaces remain protected from rust and maintain a smooth finish, then Red Oxide Primer Spray Paint is undoubtedly your best option.

Where to get the best Red Oxide Primer Spray Paint at the best prices?

Creative Resins provides supreme quality Red Oxide Primer Spray Paint at affordable prices. It can be used in industries for painting and protecting structural steelwork. It suits steel girders, metal railings, gates, and outdoor equipment. It will also adhere to surfaces that indicate rust traces. You can use it on pre-painted surfaces if dirt and loose paint have been removed. Get this product today and see the difference it can make! Call us now! – 01795 411820.

Black Granite Effect Spray: Textured Beauty

With the emergence of new, innovative technologies, it is now possible to transform ordinary glass surfaces into stunningly textured works of art. Black Granite Effect Spray Paint offers a unique way to express your creative vision, as it reproduces the look of natural black granite with an excellent finish. This spray paint is ideal for use on glass surfaces and provides an opportunity to create an eye-catching design that truly stands out. This versatile product is easy to apply and can create stunning visual effects in indoor and outdoor spaces. It’s perfect for upcycling projects or adding an extra dimension of beauty to any space.

What is Black granite effect spray paint for glass?

Black granite effect spray paint for glass is popular among those who want to give their old or dull glass surfaces a modern and sleek look. It is a specially formulated paint that produces a textured finish resembling the natural pattern of black granite rock. The spray paint contains fine stone particles, creating an authentic and realistic appearance. This spray paint can be used on various glass surfaces such as vases, mirrors, picture frames, etc. They are also easy to apply and can be done quickly without requiring much expertise or equipment. One significant advantage of using black granite effect spray paint for glass is that it provides a durable finish that can withstand wear and tear over time. It also adds an extra layer of protection to your glass surface, making them more resistant to scratches or damage caused by exposure to sunlight or moisture. Additionally, it’s cost-effective when compared with replacing the entire piece with new materials, as you can transform any old item into something brand new with just one coat!

Tips for creating a beautiful granite effect:

1. Proper usage of can:

Using the aerosol can properly to create a granite effect with spray paint is essential. One technique is to move the can twice the distance from your painting surface. It allows for a softer mist of paint that won’t oversaturate your project.

2. Control the amount of paint:

Half-pressing the nozzle will help control how much paint comes out and prevent drips.

3. Flick the brush:

To make this granite effect, spray the desired paint colour onto the surface and then take a brush and flick it at the surface to create tiny speckles.

4. Sufficient drying period:

Applying multiple layers of spray paint too quickly can lead to running or pooling, ruining the effect you’re going for. To avoid this, wait at least 15 minutes between each layer.

5. Application of accents:

To create texture, use a stiff-bristled brush or sponge to dab on accents in darker tones. Be sure to apply these accents sparingly to avoid overdoing it and ruining the overall effect.

What are the uses of granite effect Spray paint?

Granite effect spray paint is a versatile and cost-effective approach to transforming the look of your home or office. It is not limited to furniture and household items. It has a wide range of applications, from decorative to professional use.

1. Kitchen or bathroom:

The granite effect spray paint can be used in kitchen or bathroom remodeling projects.

2. Indoor and outdoor:

It is one of the most versatile aerosol paints that can be used for both indoor and outdoor projects. The spray paint can also be used on exterior surfaces to create a durable finish that will withstand harsh weather conditions.

3. Window displays:

Granite effect spray paint can be used in window displays. The unique texture and natural look of granite make it an excellent choice for creating eye-catching window displays that stand out.

4. Set design:

It is also used in set design for film, TV shows, or theatre productions. Because it gives a natural and authentic finish to surfaces, granite effect spray paint can be used to create stone walls or floors that look like they have been there for decades. Set designers can use this type of paint on props and backdrops, making them appear more realistic on camera.

The beauty of using granite effect spray paint is its application versatility. From household items like lamps and vases to professional settings such as window displays and set designs- this type of paint offers limitless possibilities in decoration and aesthetics.

How to use Granite Effect Spray Paint?

- Mask off the areas of your object you do not want to paint.

- Shake the can well before use and test it on a small area to ensure you are happy with the colour and finish. It’s vital to continue shaking for at least one full minute to ensure that all the pigments and other ingredients within the paint are adequately mixed. Skipping this step could result in uneven coverage or clumping of pigments on your surface, ruining the effect you’re trying to achieve.

- Remember to wear gloves or other hand protection throughout this process- we recommend Creative Resins’ Disposable Nitrile Gloves.

- Begin by holding the can approximately 20-30cm away from your object and apply light, even coats of paint, in a sweeping motion.

- Applying paint in thin layers is crucial to achieving a granite effect with spray paint. Starting with an even base coat, lightly dust the surface with the primary colour of choice. Let it dry completely before applying another layer of similar thickness.

- Allow every coat to dry completely before applying another layer. It’s important not to overload the surface with too much paint, which can cause drips and uneven coverage.

- Once you have achieved your desired level of coverage, leave your object to dry for at least 24 hours before handling or moving it.

In conclusion, the Black Granite Effect Spray Paint’s textured finish provides a unique layer of protection and durability to the glass surface, making it resistant to scratches, rust, and fading. With its beautiful black granite finish and exceptional protective capabilities, this spray paint will surely bring a modern touch to any home décor.

Where to get the Black Granite Effect Spray Paint at the best prices?

Creative Resins offers premium quality Black Granite Effect Spray Paint at reasonable prices. It has exceptional adhesion to glass. Call us now! 01795 411820.

Spray Painting Tips: Essential Do’s and Don’ts

Spray painting can be a great way to customise and transform your home or furniture. However, if it isn’t done correctly, it can lead to a mess and even damage the material you are painting. Let us see the best tips for spray painting to help you achieve a professional-looking finish. We explain both do’s and don’ts that you should remember when spray painting to obtain a successful outcome.

Do: Prepare Surface

The first step to achieving success with spray painting is preparing the surface. From small projects like picture frames to more oversized items like furniture, all surfaces must be clean and free from dirt, grease, or residue before painting. Aerosol paint can spread and seep through every opening, so you can lay down a plastic layer and then place a canvas-covered frame over the area you are working on. It will ensure that no paint gets on surfaces that should not be painted.

Additionally, use painter’s tape along the designated borders to avoid accidental spills or overspray. Lay down newspapers or drop cloths to protect any furniture or other items near the job site. You also must wear protective clothing such as long sleeves and eye protection when spray painting, as aerosol particles may enter the eyes or lungs if not appropriately protected.

Do: Wear Protective Gear

Spray painting is an easy and fun activity that can be done to spruce up objects around the house, from furniture to DIY projects. However, taking safety precautions before you begin spray painting is essential. Wearing gloves and a mask or goggles is necessary when using any paint aerosol. If you are working indoors, open the windows for proper ventilation. These simple steps will ensure your spray painting experience goes smoothly and safely.

Do: Use Thin Coats

Using thin coats will help you achieve even coverage over the entire surface without having unsightly runs or drips that can ruin the look of your project. To apply a thin coat, hold your can at least six inches away from whatever surface you’re spraying, and make sure that you overlap each pass slightly as you move along. It ensures an even spread of paint across the entire area, so there are no missed spots or heavy globs that could damage what you’re trying to create.

Do: Spray out the edges.

When performing a spray painting job, you should hold the can upright 6-10 inches from the surface and spray in a back-and-forth motion. Doing this will help ensure an even coat of paint, and it will also help prevent “jamming” or “stuck” issues. Additionally, you should start spraying off the edge of the surface and move inward towards the middle for more excellent coverage. Lastly, keep your arms moving when spraying so that you don’t end up with too much paint in one place.

Do: Shake the can

One of the essential steps in spray painting is to shake the can for at least two minutes before beginning your project. To ensure you have shaken enough, it helps to set a timer and keep shaking until it goes off. Your arm may get tired during this step, but you mustn’t give up too soon! When the paint is mixed correctly, it will come out more evenly, making it a better-looking finish. For best results, shake the can vigorously until all the contents are combined, and no lumps remain.

Don’t: Paint outside on hot days.

Spray paint will wear off or evaporate faster when the temperature is too high and can affect the quality of your work. So, if you’re determined to paint outdoors, proceed with caution on scorching days. The ideal outdoor temperature should range between 50 F and 90 F for the spray paint to stick correctly and last longer.

Don’t: Skip primer.

Primer is an adhesive that ensures the paint adheres to surfaces properly and avoids chipping or peeling off. It also helps fill any cracks or imperfections on the surface you’ll be painting, resulting in a smoother finish. If you don’t prime your surface before applying paint, your job will look sloppy and uneven. At worst, it won’t hold up very long and will quickly peel off. Make sure to select primers specifically designed for the material you’re working with; wood needs a different kind of primer from metal or plastic. Furthermore, applying multiple coats of primer can help ensure a more even coating.

Don’t: Spray too close.

You may be tempted to get close up when starting a spray painting project, but distance is your friend; if you start at a greater distance than necessary, you can always move closer as needed. With some practice, getting the perfect amount of paint on your project can easily be achieved by understanding how far away from the surface you should hold your can of paint while spraying.

The size and shape of the object also play an essential role in deciding how far away you should hold your spray paint from it; larger objects require more space between them and the nozzle than smaller ones do. To ensure you’re starting with the best distance, test on a piece of paper or cardboard to see how much product comes out. Always start 10 inches away, then decide if you want to spray closer.

Don’t: Ignore Drying Times

For paint to look flawless, each coat needs time to dry before you move on to the next. Waiting at least 20 minutes between coats is a must, although drying times can range from one to four hours, depending on the type and brand of spray paint used. Even though it may be tempting, never touch or feel the wet paint, as you risk smearing and ruining your work. It could also leave fingerprints on the dried paint, significantly lessening your project’s overall appearance.

Don’t: Overload the Paint

It is vital to pay close attention when using a spray gun for any project. When beginning your project, ensure not to overfill the gun with too much paint, as this will result in an uneven coating and splatter marks on your surface. Additionally, if you have already overloaded the surface with excess paint, do not add more – instead, take a step back and allow time to dry before adding additional coats if needed.

In conclusion, spray painting is a great way to give any piece of furniture or decor an instant upgrade. With the proper preparation, primer, and paint, you can be sure your project will look professional and last for years. Always practice on scrap wood before tackling a larger project. Spray painting can be a fun and rewarding experience if all precautions are taken into account.

Where to get the best spray paint?We, Creative Resins, offer premium quality spray paint at the best prices. We manufacture specialist paint for doors, glass, PVCu, and metal. We work with door, window, conservatory, and kitchen companies to offer materials, equipment, application systems, and specialized software to fulfill their decorative needs. Call us now! 01795 411820

Epoxy Floor Coatings: All You Need to Know

- Creative Resins provides high-quality epoxy floor coatings.

- All you need to know about floor coatings with epoxy.

- What are Epoxy floor Coatings?

- Creative Resins' Epoxy Floor Coating: Benefits and Considerations

- 1. Resistance

- 2. Long lasting

- 3. Strength

- 4. Protection

- 5. Cover the stain

- 6. Cost effective

- 7. Easy maintenance

- 8. Security

Creative Resins provides high-quality epoxy floor coatings.

Creative Resins has been a leading manufacturer of specialist paints and coatings for the global construction industry over the past 30 years. Our paint products are designed to protect doors, glass, PVCu, and metal from corrosion and wear. Our company takes great pride in our commitment to quality and reliability.e

All you need to know about floor coatings with epoxy.

Epoxy floors are still gaining popularity. This flooring can not only transform any space but also strengthens the concrete and protects it from harsh impacts. Let us see the advantages of the method to make your choice easier.

What are Epoxy floor Coatings?

It is a highly resistant material made of epoxy resin and many other substances. Epoxy floor coating creates a specific chemical reaction that gives the floor certain qualities. Thus, the surface stability and new tolerance achieved through chemical reactions are epoxy floors’ main characteristics.

Typically, it is applied to concrete floors to create a high-performance, durable, smooth surface that can withstand heavy loads for many years. You can also use it for warehouses, industrial sites, commercial buildings, and residential houses.

Creative Resins’ Epoxy Floor Coating: Benefits and Considerations

Durability and good looks are some of the advantages of epoxy floors. Below you can find a list of the main features of this method that make it worth your attention.

1. Resistance

Epoxy can strengthen your basement by keeping it away from damaging elements.

- It is so resistant to impact that concrete will no longer crack due to repulsion accidents.

- It can withstand certain levels of heat (200 Fahrenheit or more). These capabilities make commercial kitchen epoxy floor coatings and garage floor epoxy coatings in demand these days.

- Chemicals will not affect epoxy. So you can clean the paint/concrete without damaging it.

- The material is water resistant making it a suitable waterproofing solution.

2. Long lasting

When installed correctly, you can be sure that epoxy coatings last longer than laminate, carpet, and tile floors.

3. Strength

When you use epoxy floor paint for concrete, you can increase the weight-bearing capacity of the concrete. Sometimes the surface strength of concrete can be grown from 3,000 to 10,000 PSI. In addition, the surface is stable enough to withstand heavy loads and wear and tear.

4. Protection

Being a sealant, epoxy resin protects the concrete from various defects and corrosion. It acts as a safe overlay.

5. Cover the stain

Epoxy floor paint can transform your space into a finished, smooth, and sleek surface. Besides, the material covers the previous defect and hides it. Epoxy is offered in various colors and can be mixed with decorative quartz/mica chips for a masking effect. Epoxy metallic floor coatings are another option for enhancing the polished vibe.

6. Cost effective

Being affordable and durable, epoxy floors are a cost-effective solution for almost any purpose. Thus, the epoxy concrete coating is the best way to go as it not only gives a great look but is also waterproof. Plus, there is no need to purchase new tile/vinyl plus additional installation costs.

7. Easy maintenance

Simple maintenance is another advantage of the material. It is effortless to remove any contamination. Moreover, bacteria/germs/dirt also do not stick to epoxy, making it a practical and hygienic coating.

8. Security

This feature is one of the main factors for using the material in industrial and commercial projects. So, by investing in high-quality industrial epoxy floor coating, epoxy commercial floor coatings, epoxy garage floor coatings, swimming pool coatings, epoxy staircase coatings, etc., you get a neat and polished look for your space. Still, you also get a safe workplace.

Are you looking for superior epoxy coatings without breaking the bank? Look no further than Creative Resins. Our team provides the highest quality epoxy coatings at competitive prices. Contact us today at 01795 411820 for more information.

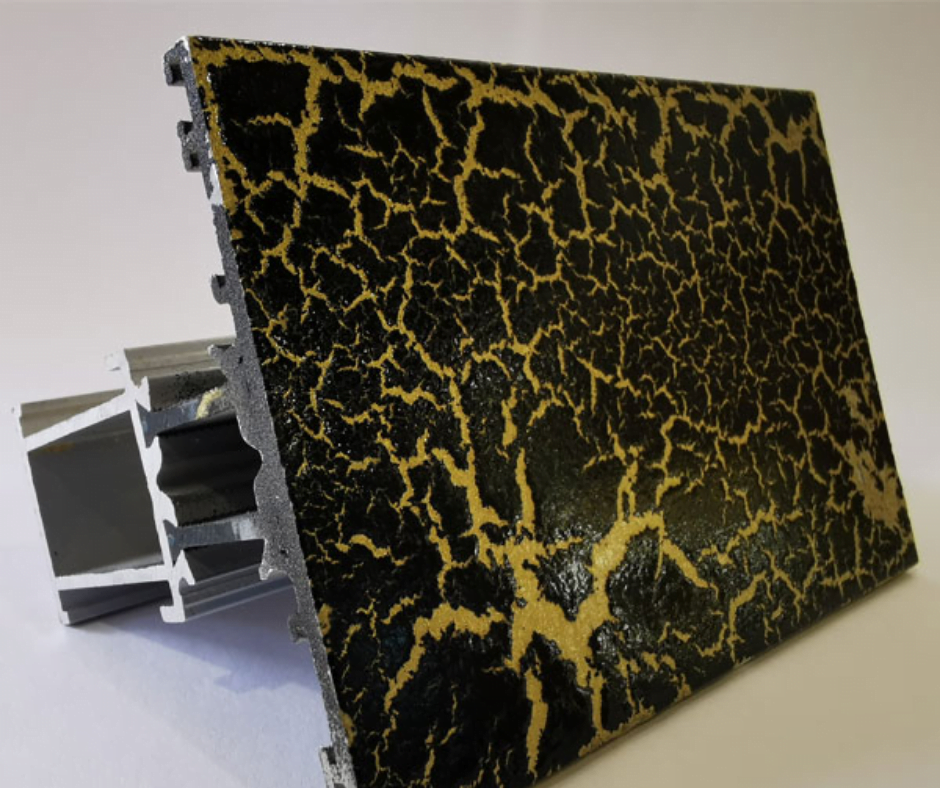

PlasPaint Crackle Effect Usage Guide

If a visually striking crackle finish is what you seek, then Creative Resins’ PlasPaint Special Effect Crackle solution is what you should buy. The solution is ideal for use on glazing cassettes, uPVC windows, aluminium, and steel surface. This crackle effect solution comes pre-blended and ready to use. It can very easily be applied using a conventional spray gun.

Another thing that customers like about this solution is the wide range of colour options they get to choose from. From black and gold to white and silver, you can achieve a variety of mesmerizing effects with PlasPaint’s Crackle Effect solution. Suffice to say, whatever surface you choose to embellish with the crackle effect, will stand out in any interior setting. The finished look is bound to leave you stunned.

If you wish to use PlasPaint’s crackle effect solution on your next project, then we’ve got the perfect guide below to help you achieve superb results.

So without much further ado, let’s get started.

1. Preparation

Preparation is key to a good paint job. To begin with, you need a surface that is clean and dry. So make sure the surface you’ve chosen to paint is free of dust, rust, or oil stains that might hinder your process. Once you’ve determined that your surface is clean and dry, it is now time to make sure that any other areas near your surface are adequately covered to avoid over-spray.

Proceed to cover or tape parts of your surface that you don’t intend to paint. We also recommend working in a well-ventilated area. This is preferred as most paint solutions work better in an environment with temperatures ranging from 10 ̊C to 25 ̊ C.

Also, wear a protective mask and gloves to protect your skin when painting. Follow local recycling guidelines to responsibly dispose of empty paint cans.

2. Apply Base Layer

It is necessary to first apply a coat of paint that will serve as your underlayer before you start spraying the crackle effect solution. The underlayer solution will be the colour that shines through the crackle after the top layer has been applied. We recommend going with a strong contrast to make the crackle effect stand out even more.

You can also try using different colours if you want different tones to show up through the crackle. For instance, you might want to use different colours to paint different parts of the furniture to achieve a unique transition effect.

Once you’re done applying the base coat, leave the surface to dry for at least 45 minutes. Make sure you aren’t leaving your surface to dry for more than 24 hours. When the base layer is touch dry, that’s when you proceed to apply the crackle effect.

3. Applying the Crackle Effect

Before spraying the crackle effect, we recommend giving your paint can a good enough shake. 2-3 minutes of continuous shaking would suffice. Then, apply the crackle effect solution carefully to your surface.

Make sure to hold the spray gun at least 15 to 20 cm away from the surface when applying. We recommend applying at least 2 to 3 layers for desired results. Make sure your spray gun is moving consistently across the surface. Stop once you’ve coated the entire surface. This is where you let the crackle effect solution do its job it will instantly crackle erratically across your surface. Wait for at least 24 hours for the paint to fully cure.

Quick Tip to Achieve Different Crackle Effect

PlasPaint’s Crackle Effect Solution allows you to easily adjust the effect resulting from the paint to best cater to your project’s style. To achieve a fine crackle effect, you can opt to apply thin coats. For a heavier crackle effect, on the other hand, you can proceed to apply a thicker coat. You can choose to experiment on a scrap surface to test the various levels of crackle you can achieve before you proceed to paint your final object.

Applying a second coat once the first paint coat has dried, can also help you enhance the intensity of your crackle effect. If a dramatic look is what you are going for, then this tip could come in handy.

4. After Paint Work

Once 24 hours are complete and your paint has completely cured, we recommend applying an extra layer of protection with the additional application of a paint solution. This extra layer will protect your painted surface against damage from dust, moisture, and scratches. We recommend you go with a gloss or matte final layer for the finishing touch.

Once this final layer has also cured, your job is done and your surface is ready. All that is left for you to do right now is sit back and feast your eyes on the fruit of your labour.

You can buy the PlasPaint Crackle Effect solution right here.

Checkout Our Video: