Durable, Resistant Corrosion Metal Paint

The revolutionary temperature and water-resistant corrosion metal effect glass paint can withstand extreme temperatures, resist water damage, and remain impervious to fading or scratching. This innovative product has been specially formulated to provide long-lasting protection and beauty to your glass surfaces. Whether it’s windows, doors, or decorative pieces, this remarkable glass paint is designed to endure the harshest conditions without compromising aesthetics. Say goodbye to peeling, chipping, or dullness – with this incredible solution, your glass surfaces will retain their vibrant colors and flawless finish for years. Enter the revolutionary Corrosion Metal Effect Paint – an innovation in surface protection that promises to keep your surfaces looking brand new for years.

What is Corrosion Metal Effect Glass paint?

Corrosion metal effect glass paint is a paint that gives any old or new surface a rustic and aged appearance, adding character and intrigue to an ordinary item. This rust-effect paint is remarkable for its ability to mimic the natural weathering process of metal corrosion. The paint contains unique pigments that react with air and moisture, causing them to oxidize over time. This gradual oxidation gives rise to the distinct orange-brown hues typically associated with rusted metal surfaces. It is realistic and impressive to see and feel the transformative power of a corrosion metal effect glass paint that not only replicates the look of rust but also withstands the test of time. With this innovative paint, you can achieve an authentic and mesmerizing rusty appearance on surfaces without worrying about it fading or scratching away. The innovative formula used in the corrosion metal effect glass paint is unique. It all starts with a base coat that contains real metal and iron particles. When these particles come into contact with an oxidation solution, they begin to rust, creating a stunning and unique metal effect on the glass surface. Some oxidation solutions produce an even uniform corrosion effect on the painted surface. It can help create a weathered look or simulate aged metal objects.

On the other hand, more aggressive solutions can generate an uneven and unpredictable corrosion pattern. It adds a touch of randomness and complexity to the finished piece, making it visually intriguing. How the material is positioned during application can impact the final result, emphasizing certain textures or creating unique patterns. For instance, painting the glass surface horizontally may create a smoother finish, while applying it vertically could give rise to streaks that mimic rusted metal.

Features and Benefits of Corrosion Metal Effect Glass Paint

Water Resistant

One of the key advantages of our corrosion coating cycle is its water resistance. Water can significantly threaten structures as it promotes oxidation and rust formation. However, with our innovative technology, we have found a way to create a protective barrier that repels water l. It not only extends the lifespan of the material but also reduces maintenance costs significantly. Not only does our metal corrosion effect glass paint provide an exceptional aesthetic appeal, but it also boasts impressive performance features. Offering resistance to water exposure, this paint is built to withstand harsh climates without fading or deteriorating. It ensures longevity and durability for outdoor signage, architectural elements, or interior design accents. Metal corrosion Effect paint prevents water molecules from coming into contact with the surface by forming a tight seal that waterproofs the material. It helps to minimize oxidation and decrease the chances of rust formation.

Scratch Resistant

Scratch resistance is a crucial feature in metal corrosion effect paint. Paints that boast scratch resistance ensure that your beautifully painted surfaces stay looking brand new for longer, even in high-traffic areas. It means that not only will your corrosion effect paint have a stunning rustic appearance, but it will also be strong enough to resist scratches from keys, jewelry, or any other object that may come into contact with it. The benefits of scratch resistance extend far beyond just aesthetics – they also help to protect your investment.

Temperature Resistant

When restoring and protecting high-heat surfaces, finding a product that can withstand extreme temperatures is crucial. You can use Corrosion Metal Effect paint – a game-changer in the world of coatings. Unlike traditional paints that may fade or peel when exposed to heat, this innovative formula has been specially formulated to retain its vibrant color and durability even under extreme conditions. One of the critical features of Corrosion Metal Effect paint is its temperature resistance. Able to handle high-heat environments like no other, this product ensures that your surfaces stay protected and attractive for extended periods.

Fade Resistant

The fade resistance property is achieved in metal corrosion effect glass paint through the ingredients used in the formula. These fade-resistant properties ensure that your painted glass surfaces retain their vibrancy and shine for years. High-quality pigments are blended with durable resins that provide excellent adhesion and resistance against UV rays, harsh weather conditions, and even repeated contact with water. This combination creates a protective barrier shielding the pigments from fading or deteriorating. With vibrant colors that don’t lose their intensity or become washed out over time, you can confidently display your painted glass surfaces without worrying about them appearing dull or unsightly too soon.

Application and Longevity of the Paint

One of the most impressive aspects of metal corrosion effect glass paint is its versatility. It can be utilized for domestic and commercial purposes, making it a valuable asset in various settings. This innovative paint adds elegance and uniqueness to the décor in bars, hotels, and restaurants. Its realistic and impressive appearance creates a mesmerizing ambiance that captivates guests. The beauty of the metal oxide effect kit lies in its ability to create an aged and corroded metal effect. This innovative product can be applied over any painted surface, instantly transforming it into a stunning piece of aged artwork. Unlike traditional paints or coatings that quickly fade or scratch over time, this glass paint is temperature and water-resistant, ensuring that your corrosion effect remains intact for years. There is no need to worry about your masterpiece losing its luster under harsh weather conditions – it will continue to evoke the essence of aged metal, even after rains, storms, and scorching sun. Once the corrosion phase is complete, it’s essential to consider preserving the appearance of metal surfaces while ensuring a high resistance level. It is where topcoats come into play. These topcoats protect against external factors such as temperature and water and provide an aesthetically pleasing matte finish that adds sophistication to any surface. A painted surface with a rustic effect can bring an edgy yet elegant aesthetic to any space, whether it’s indoors or outdoors. It means you can enjoy rusty metal’s weathered charm without worrying about fading or scratching.

Where to get the Corrosion metal effect paint at the best prices?

Creative Resins offers premium quality corrosion metal effect glass paint at affordable prices. Its unique formulation provides temperature and water resistance, making it ideal for indoor and outdoor use. Say goodbye to faded and scratched paint jobs, as Creative Resins’ corrosion metal effect paint is designed to withstand even the harshest conditions with a 10-year internal and external warranty. Transform your surfaces today and experience the difference! Call us now at 01795 411820.

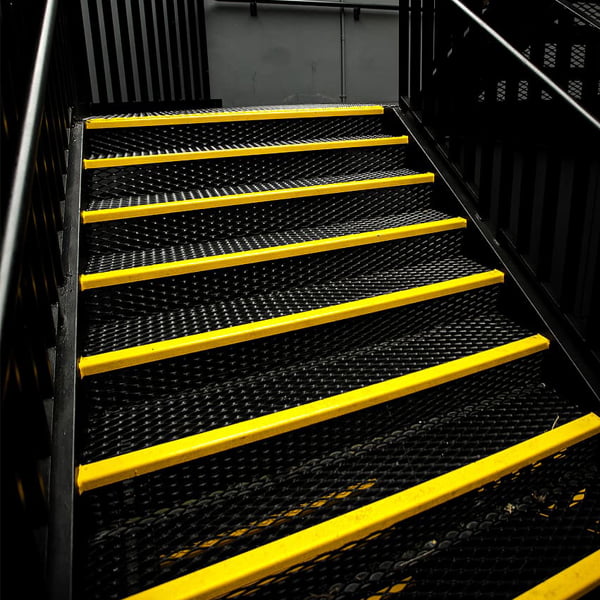

2K Non Slip Metal Paint – Matt 8018

Looking for a good anti-slip grip paint for metal. Well, look no further than Creative Resins’ 2K Anti Slip Paint with Matt finish.

Creative Resins brings to you a powerful matt metal paint with Anti Slip properties. This non-slip paint for metal is designed for areas that require excellent Anti Slip Properties to Class 3 UNE-ENV1263. This non-skid paint for metal can work as a sheet metal paint as well as a non-slip paint for metal stairs and other metal surfaces. The slip-resistant paint for metal is available in any colour. The paint also provides excellent anti-corrosive protection when used with Creative Resins Epoxy Primer 7011.

This is an Anti Slip acrylic topcoat with a matt finish combined with an aliphatic hardener that gives excellent colour and gloss retention. This 2K anti slip matt metal paint is a premium high quality product which provides excellent adhesion to metals. It also has very good resistance to citric acid, Ammonia, Bleach, and Gasoline.

This Anti Slip product is classified as Class 3 UNE-ENV1263 skid/slip resistance for surfaces submitted to heavy traffic, requiring high mechanical resistance, scratch and chemical resistance (parking areas, steel floors and staircases, fire escapes, walkways). The paint can also be applied using a conventional spray gun or applied with a standard paint brush or roller.

Some Applications:

- Non-Slip Coating for Steel

- Non-Slip Paint for Metal Ramps

- Non Skid Paint for Metal Stairs

- Exterior Anti-Slip Metal Paint for Steps

Non Slip Matt Metal Paint – 8018 can be used for:

- Parking Areas

- Steel Floors

- Metal Staircases

- Loading Bays

- Walkways

1K Direct to Metal Paint

Looking for the best direct to metal paint in the UK? Well, Creative Resins has just the thing you are looking for!

Creative Resins brings to you a direct to metal paint that can act as a Primer and topcoat for metal. This direct to metal paint can be used for both internal and external purposes. The metal acrylic paint exhibits high anti-corrosive properties. This industrial metal paint is specially designed for direct application without the need for a separate primer.

This is an industrial quality transparent Acrylic Polymer that provides an exceptional adhesion directly onto metal as well as delivering an excellent anti-corrosive coating. You can also use this as a direct to metal spray paint for extra convenience using a conventional paint spray gun. It can also be easily applied using a standard paint brush or roller. It’s ideal to use as metal shed paint, gates and railings, metal stairs and metal garden furniture.

This single component product is a Dual Primer and Topcoat specifically formulated to provide an outstanding performance on Steel, Galvanised material, Stainless Steel and Aluminium. Its performance on galvanized metal has also earned it the title of one of the best direct to galvanized metal paint in the industry today.

It is available in any colour as it can be pigmented using Creative Resins concentrate UT colour pigments and the Colour Match software to provide colour matches for RAL, NCS, Pantone and numerous other corporate colour reference cards.

1K Direct to Metal Paint can be used for:

- Metal Shed

- Metal Gates

- Metal Railings

- Metal Stairs

- Metal Garden Furniture

Available In Finish:

- Matt

- Gloss

5 Mistakes To Avoid While Painting Metal Roof

How can avoid mistakes while doing metal roof painting? Painting a metal roof can involve various tasks. You can get excellent roof treatment and painting results by avoiding common errors. The paint must be specialized, but the painting technique remains the same. Let us see the most common mistakes made that you should avoid.

1. Use the leftover paint

As mentioned, surfaces require different types of paint. The paint used on the remaining areas of the house will not necessarily work on metal roof structures. The primary reason is that the roof material differs from the rest of the house. Paint used to coat wood will never work in roofing solutions. Paints on metal surfaces are usually rust and corrosion resistant and can also be heat-reflective. Most importantly they must be weatherproof.

2. There is no sealant

Another common mistake is neglecting to use a suitable primer before applying the paint top coat. In cases where the primers are not applied the painted top coat can peel. It is one of the biggest mistakes people make when painting roofs. The correct primer depends upon the type of metal roof you are painting beit steel galvanized steel or aluminium. The primer provides a chemical bond and anti-corrosion properties thus ensuring its long life. Additionally, the use of primers requires a lot of research. Each primer has different ingredients and sometimes different application methods. Primers are specific to the type of metal you are painting.

3. Paint not being energy saving

Energy-saving paints are opaque and reflective, making them significantly thicker and more cost-effective in terms of energy savings. Titanium dioxide and acrylic make them more beneficial, easier to use, and more productive.

4. Incorrect application methods

Common mistakes most people make are not applying enough paint and using the wrong product.

5. Not paying enough attention

After you finish painting, you should have your own metal roof cleaning routine every six months. A mixture of water, liquid detergent, and bleach will be necessary to ensure that cleaning is done correctly and effectively. You should also remove debris periodically to avoid insects. Rough patches or bald spots in the paint should be detected and repaired as soon as they are found.

Avoid these common mistakes most people make when painting a metal roof.

Where to buy metal roof paints at the best prices?

Creative Resins provides premium quality metal roof paints and primers at affordable prices. Call us today to learn about our unbeatable prices and selection of metal roof paints. We look forward to helping you find the perfect solution for your needs!

7 Easy steps to paint metal surfaces

Applying a coat of paint is a quick and easy method to extend the life of metal surfaces. However, painting metal surfaces require a specific technique and most importantly the correct choice of paint, Doing so will help to extend the life of the metal surface and ensure that it is protected and looks at its best for many years.

Follow this guide to painting metal surfaces the right way.

Preparation for painting metal surfaces

Refurbishing your home’s metal surfaces is much cheaper than replacing them, The cost of new Metal gates and fences, steel windows, etc might make you want to dip your paintbrush in, but you must be prepared to do a good job. Here are some tips for preparing the metal surface.

Choose the suitable primer.

Choosing a primer can be challenging. You have to consider the surface condition of your metal as well as the type of metal you intend to paint. Some surfaces are in good condition and only require one primer coat, while others require two coats. Some can be painted using direct-to-metal paints that offer a primer and top coat combined within the same product. Always choose a corrosion-resistant base to protect the metal from rusting. Metal Primers are normally available in either a spray application or can be applied using a brush or roller.

Choosing the right tools

Knowing which tool to use will make the painting successful. Brushes and rollers differ in application compared to spray paint.

Paint Spray: Avoid brushstrokes with lots of nooks and crannies on irregularly shaped objects. This method is the quickest and fastest drying option. Spray paint creates a thinner layer so two or three coats may be required.

Brush or Roller: Although this method takes longer to apply, the brush or roller technique applies a thicker layer to outdoor items that need more protection from wind, sun, and rain. Painting with a brush and roller provides a more controlled application indoors or outdoors.

Safety precautions

Safety is at the forefront of any project you work on, and metal painting is no exception. Working with corroded metal poses potential health risks. When removing rust from old metal, working in a ventilated environment is essential. You must wear gloves, eye protection, and a face mask to prevent injury or illness.

1. Removing rust and old paint

Rust and old paint can prevent new paint from adhering correctly to the metal surface, causing the paint to peel off prematurely. To prevent this, you need to remove it before painting. Depending on the amount of rust, you may need one or more rust removal tools.

- Wire brush for daily surface rust

- Wire brush drill attachment for large areas with lump rust

- Soak in liquid rust remover to remove even the toughest rust stains

2. Clean the metal

After removing rust and peeling paint, clean the surface with mineral spirits, a petroleum distillate commonly utilized as a paint thinner. Brushing the metal with mineral spirits instead of water will prepare the new paint to adhere to the metal surface. Avoid using water to clean metal as it will cause more corrosion over time.

3. Sanding metal

Like a blank canvas, painting metal projects works great with small etchings on the surface to hold the paint and primer in place. To do this, you must sand the entire metal surface with a scuffing pad or fine-grit sandpaper.

4. Apply primer

With your surface ready to paint, it’s time to apply a primer to the metal. For Steel, Galvanised steel, and even aluminium you may need to apply a layer of zinc chromate primer or Red Oxide primer first to prevent further deterioration. Use a sprayer for metal surfaces with multiple cracks, and use a brush or roller if you apply a traditional primer. Apply two coats and permit the primer to dry according to the manufacturer’s instructions.

5. Metal coating

After the primer is completely dry, apply a quality topcoat of your chosen colour to the newly primed metal using a brush, roller, or paint sprayer. Allow the coat to dry completely and apply another coat if you are using a brush or roller. Repeat the process and complete three thin coats if you are using a paint sprayer.

6. Paint treatment

Although paints like acrylic dry relatively quickly, you may want to wait a day or two for the surface to fully cure.

7. Complete with TopCoat

To avoid chipping, rusting, or fading make sure that the topcoat application is thick enough. Be sure to choose a topcoat that is formulated for metal and that is also designed to withstand the elements. You can apply topcoats with a sprayer, roller, or paintbrush.

Who provides the best paints for metal surfaces?

We, Creative Resins, provide high-quality paints for metal surfaces at the most competitive prices. Give us a call today to learn more about our products and services.

Metal Corrosion Effect – Glass Paint – Creative Resins

This unique rust or metal corrosion effect paint will naturally transform any new or old surface into a pristine, rusted surface. It is realistic and impressive to see and feel and can be used for domestic and commercial purposes such as bars, hotels, restaurants, etc.

Our corrosion coating cycle is a natural process that transforms the material into a solid corrosion surface that is resistant to water and temperature. Our formula uses a base coat containing real metal and iron particles that rust when activated by our oxidation solution.

Our metal oxide effect kit can be applied over any painted surface to create an aged corrosion metal effect. Once the corrosion phase is complete, involving one of our high-tech plaspaint matt topcoats will preserve the appearance and provide a high level of resistance. A painted surface with this rust effect can be used indoors and outdoors with a warranty of 10 years.

An evenly corroded or uneven surface can be obtained depending on the oxidation solution used. The effect also depends on how the material is positioned during application.

Using an activator on vertical surfaces creates a filtering effect where the oxidizing liquid flows under the surface to form oxidation streaks. On horizontal surfaces, the liberal application of the oxidizing agent produces large spots with liquid pooling and deeply colored oxidation. Finally, both applications will mimic the rusted metal found outdoors over the years.

The results are authentic, with surface textures varying from slightly rough to fine – just like the real thing.

2K Acrylic Metal Gloss Paint – 8040

Looking for the best Acrylic paint for Metal, then look no further than Creative Resins iconic line of industrial metal paints.

Creative Resins brings to you the perfect paint for all types of metal using an Acrylic PU Gloss 8040. The Gloss finish Acrylic PU topcoat is designed for use over our Primers and Undercoats. This metal gate paint is suitable for both internal and external applications and exhibits exceptional Anti-corrosive properties when used with our Epoxy Primer 7011. Acrylic PU Gloss 8040 can be used for all types of architectural steel where a quality finish is demanded.

This metal topcoat spray paint also exhibits excellent scratch and mechanical resistance. Moreover, the paint comes with 10 years internal as well as external warranty.

This is an acrylic PU topcoat with a gloss finish combined with an aliphatic hardener that gives excellent colour and gloss retention. This is a premium high-quality product that provides excellent adhesion to metals while offering excellent outdoor weather and UV protection. It also has good resistance to citric acid, caustic soda, and various solvents. It is available in any colour including metallic finishes such as Gold, Silver etc.

2K Acrylic Metal Matt Paint – 8018

Looking for a premium quality exterior metal door paint. Well look no further, as we at Creative Resins have just what you are looking for.

Creative Resins brings to you the perfect outdoor metal paint in the form of Acrylic PU Matt 8018. This metal outdoor paint is designed for use over our range of primers and undercoats. It is an industrial grade paint that is perfect for metal garage doors, metal railings as well as other metal outdoor surfaces and exteriors. It also offers incredible anti corrosive properties when used in conjunction with our range of specialised metal primers.

This is acrylic PU topcoat with a matt finish combined with an aliphatic hardener gives excellent colour and gloss retention. It is easily applied using a conventional spray gun. This outdoor metal spray paint is a premium high-quality product which provides excellent adhesion to all metals, while offering excellent outdoor weather and UV protection. It also has good resistance to citric acid, caustic soda and various solvents. It is available in any colour.

Creative Resins is the best supplier of paint for outdoor metal in UK. Our outdoor metal paint comes in a wide range of colours and size options. You can choose between 1.2 Ltr, 6 Ltr, and 30 Ltr solutions which includes the hardener. 1 Litre of this paint will cover approximately 6 SQM of area.

2K Anti Slip Paint for Metal

Creative Resins brings to you an anti-slip paint for metal surfaces that are designed for areas that require excellent Anti-Slip properties to class Class 3 UNE-ENV1263. The anti-slip coating for metal is available in both Matt and Gloss finish and is also available in an extensive range of commercial colours. It is widely lauded as the best exterior non slip metal paint for steps and other metal floor surfaces.

This high performance metal paint exhibits exceptional anti-corrosive properties when used with our Epoxy Primer 7011.

The paint can be applied with a conventional spray gun or simply by hand using spraybrush or roller. This anti-rust and anti-slip paint is perfect for metal surfaces such as steel stairs, loading bays and walkways where health and safety is paramount. Needless to say, if your are looking for the ideal anti-slip for metal ramps or the perfect anti-slip paint metal stairs, Creative Resins’ 2K anti slip metal paint will suffice.

This is an industrial Anti Slip acrylic topcoat with a gloss or matt finish combined with an aliphatic hardener that gives excellent colour and gloss retention. This is a premium high-quality product which provides excellent adhesion to metals. It also has very good resistance to citric acid, Ammonia, Bleach, and Gasoline and can withstand heavy footfall as well as mechanical loads.

It is available in any colour. This Anti Slip product is classified as Class 3 UNE-ENV1263 skid/slip resistance for surfaces submitted to heavy traffic, requiring high mechanical resistance, scratch and chemical resistance (parking areas, steel floors and stair cases, fire escapes, walkways).

Anti Slip Gloss Metal Paint – 8040 can be used for:

- Parking Areas

- Steel Floors

- Metal Stair Cases

- Loading Bays

- Walkways

Metallic Glass Paint – Infill Colour Pigments

Looking for quality metallic paint for glass? Well you’ve come to the right place. Give sections of your decorative glass design a remarkable metallic finish with Creative Resins’ Metallic Infill Pigments. This resin is available in three unique finishes that will give your design or glass surface a unique and breathtaking infill effect. You can choose from variants such as ‘Gold Shimmer’, ‘Silver Dollar’ and ‘Copper Wire’ to give your surface that exclusive and affluent look.

Approximately 75ml of metallic glass paint added to 1ltr transparent base will cover approximately 4sq Mtrs of surface area.

The rich concentrated metallic pigments come ready prepared to simply mix into the Clear Colour Base and Hardener. They can be applied easily using an application bottle or pipette. Moreover, the glass metallic paint provide excellent adhesion and are totally weather and UV resistant.

You can grab these pigments in volumes ranging of 125ml, 250ml and 500ml, based on your requirements.